Attic ‘High Wall’ Airsealing

Blog post by Eli Feldman. Eli has working as a HERS rater with Power House for two years, providing field inspection and energy modeling - he is a critical member of the HERS rating team.

“‘I’ve seen a lot of different types of building strategies and also seen how effective those different strategies have been. I recently graduated from Umass Amherst with a bachelor’s degree in mechanical engineering. During that time I studied a lot of fields adjacent to construction. From heat transfer to load calculations, I studied a wide range of subjects that are all a part of building science and technology. I’m excited to see where the industry goes and how technology progresses in the future.”

Attic walls can be insulated and air sealed effectively if the proper care is taken to construct the assembly the right way. The big picture to keep in mind is that you need to prevent the air in the attic from coming down into the interior wall cavities; this can lead to things like wall outlets, light switches, or plumbing fixtures on interior walls leaking during the blower door test.

Foam vs. cellulose + rigid board

Air sealing can be done most cost effectively with rigid foam board sealed at the seams with spray foam to the attic side studs on the attic wall. It’s important to seal the foam board sections to each other as well as to the framing members along the top and bottom plates of the wall.

A more expensive but easier to implement solution, is closed cell spray foam insulation on the back side of the attic wall once the drywall is hung. This method alleviates most of our concerns about air sealing, as the foam is an airbarrier and effective vapor control at 3”+ . Yet spray foam takes a lot of carbon to manufacture, so it’s not perfect.

Our ideal solution would be filling the attic wall stud cavity with dense pack cellulose and then nailing and foaming around the edges of an insulating rigid board with spray foam to the attic side of the wall. Dense pack cellulose does a good job of slowing down air flow (though is not an airbarrier), and with the rigid air barrier behind it and the drywall in front of it, these systems work in conjunction with each other to reduce airflow as much as possible.

Stove flue penetrations and seam sealing

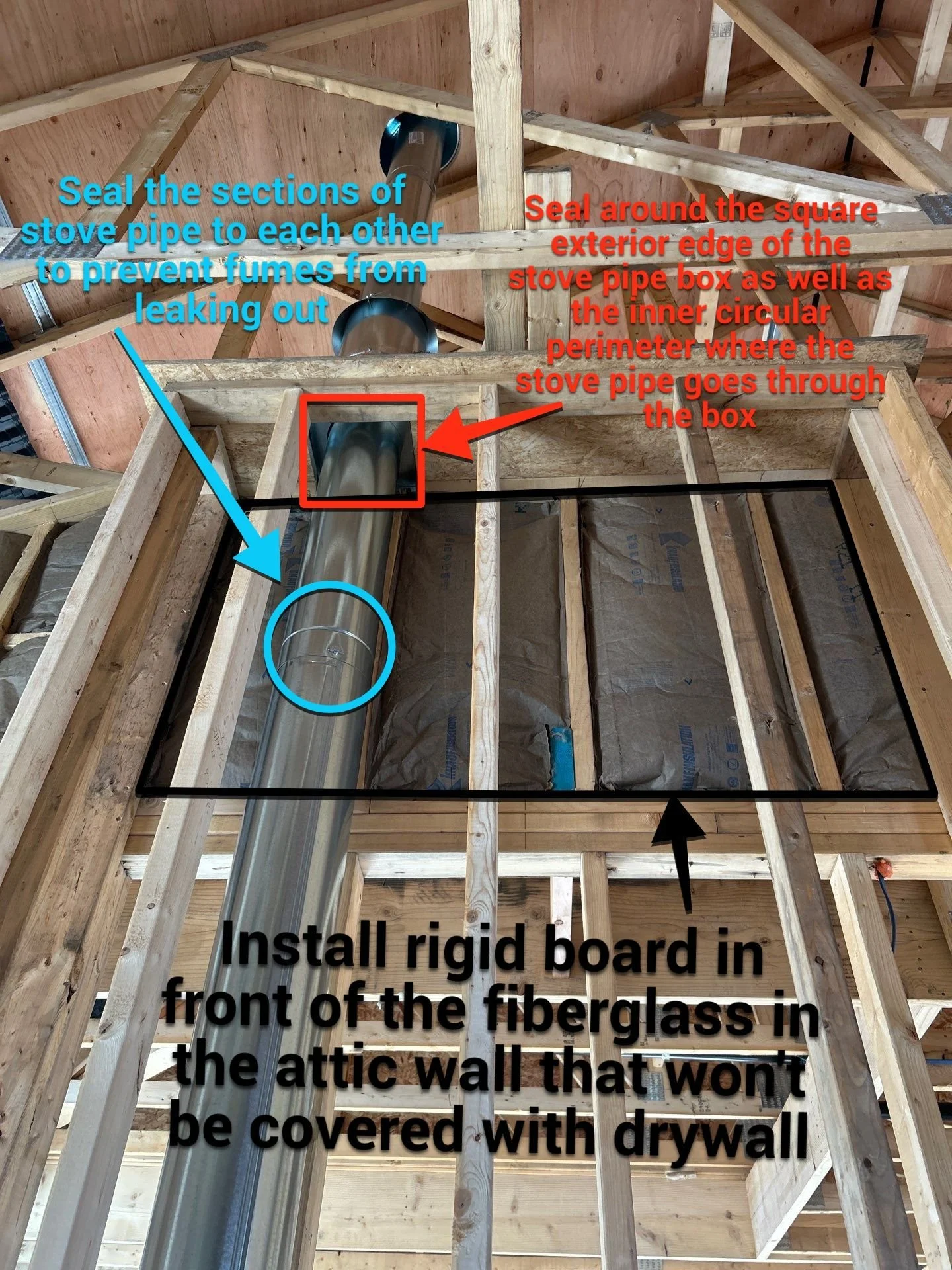

Another common issue that comes up is when there is a stovepipe or chimney that runs along the attic wall. The framed box that encloses the stovepipe or chimney is considered dead space, so unless there is another air barrier on the front side of the attic wall that encloses the insulation in the cavity, air can travel through the fiberglass from the opening around the fireplace. If there isn’t a rigid air barrier behind the attic wall, it can also travel directly from the attic to conditioned space through electrical and plumbing holes in interior walls. Making sure that the insulation in the attic wall has an air barrier on both sides of the studs is key to preventing air leakage from the attic into conditioned space.

Stovepipes can also be a tricky detail to get right, and are complicated by the need to comply with fire code and the obvious safety hazards of heat and ventilation. I have often seen stovepipe sections screwed together with no gasketing or sealing between the sections of pipe. This is not only bad for the general air tightness of the house, but also the fumes from the propane, natural gas, or wood will still be able to enter the house through the gaps between stove pipe sections. It’s important to seal the sections of stovepipe to each other to prevent air from leaking in from outside and fumes from leaking out of the fireplace.

It’s also important to properly seal around the stovepipe where it penetrates through the thermal envelope. The most common method I see for running the stovepipe out of the envelope is routing the pipe through a metal box in the sloped or elevated ceiling above the fireplace. This box has a hole for the pipe section to go through and vent out of the roof. This seems to be the most effective method for venting as long as the stovepipe box is sealed around the inner perimeter of the circle where the actual pipe section runs through the box. Fire rated caulk is what we recommend for sealing that gap because it complies with fire code and makes a strong enough seal to prevent outside air from coming in.

Attic walls done right gives peace of mind and easy compliance

Attic walls can be tricky details to get right, but if done correctly can be just as air tight as regular exterior walls. I’ve seen many houses where the proper steps were taken to install a rigid air barrier on the interior and exterior sides of gable ends and the house passed with flying colors.